During inspections of a seal strength tester, there are several signs of wear or damage that you should look out for.

Here are some common signs to watch for:

Physical damage: Check for any signs of physical damage to the device, such as cracks, dents, or scratches on the housing or components.

Loose or damaged components: Check for any loose or damaged components, such as screws, bolts, or other fasteners, that may affect the operation of the device.

Wear and tear: Inspect the components of the device, such as the grips, jaws, and clamps, for signs of wear and tear. Over time, these components may become worn or damaged, which can affect the accuracy of the test results.

Calibration issues: If the device is not properly calibrated, it may provide inaccurate results. Check the calibration status of the device and ensure that it is calibrated according to the manufacturer’s instructions.

Inconsistent results: If the device is providing inconsistent or unexpected results, it may be a sign of a problem with the device or the testing process.

Lack of maintenance: If the device has not been properly maintained, it may be more prone to wear and damage. Check for any signs of improper use or lack of maintenance, such as buildup of dirt, debris, or other contaminants.

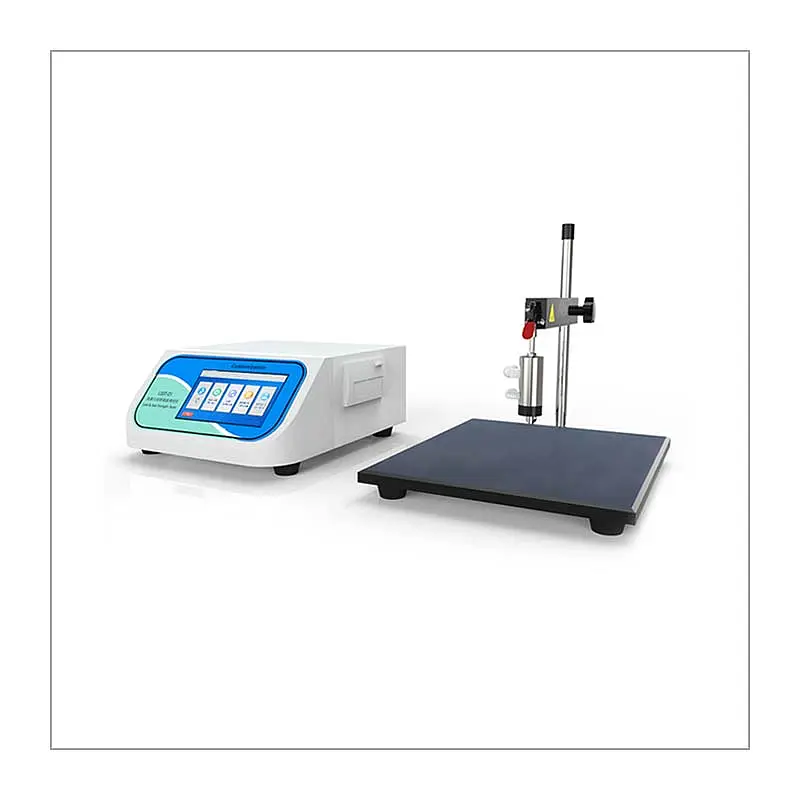

If any of these signs are present during an inspection of the seal strength tester, it may be an indication that maintenance or repairs are needed. seal strength tester It’s important to address any issues promptly to ensure that the device is functioning properly and providing accurate results.

What are some common methods for repairing a seal strength tester?

The specific methods for repairing a seal strength tester can vary depending on the type and extent of the damage or wear.

However, here are some common methods for repairing a seal strength tester:

Component replacement: If a specific component of the device is worn or damaged, it may need to be replaced. This could include components such as grips, jaws, clamps, or other fasteners. Replacement components should be sourced from the manufacturer or a qualified supplier to ensure proper fit and function.

Calibration: If the device is providing inaccurate results, it may be due to a calibration issue. Calibration should be performed by a qualified technician using the appropriate calibration equipment and procedures.

Cleaning and maintenance: If the device has not been properly maintained, it may require cleaning and maintenance to restore proper function. This could include cleaning the components, lubricating moving parts, and replacing worn or damaged components.

Adjustment or realignment: If the device is not functioning properly, it may require adjustment or realignment. This could include adjusting the grips or jaws, realigning the load cell, or recalibrating the device.

It’s important to note that repairs should only be performed by a qualified technician who is familiar with the specific device and the proper repair procedures. Improper repairs can lead to further damage and safety issues.

Proper maintenance and inspection of a seal strength tester can help prevent the need for repairs and ensure that the device is functioning properly. By following the manufacturer’s guidelines and consulting with a qualified technician, companies can ensure that their seal strength testers are functioning properly and providing accurate results.