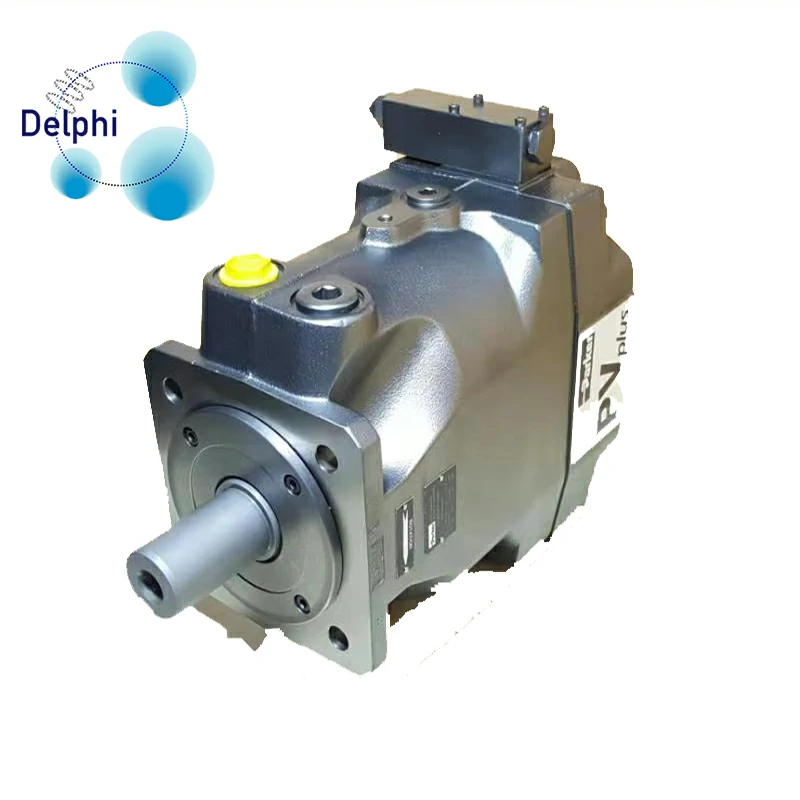

A 40 gpm 3000 psi hydraulic pump is a type of hydraulic pump that is designed to provide a maximum flow rate of 40 gallons per minute (gpm) and a maximum pressure of 3000 pounds per square inch (psi). This type of pump is typically used in applications where high flow rates and high pressures are required, such as in heavy-duty hydraulic systems used in construction, mining, or oil and gas industries.

When selecting a 40 gpm 3000 psi hydraulic pump, it’s important to consider several factors, including:

System requirements: Ensure that the pump is compatible with the requirements of your hydraulic system, including flow rate, pressure, and power requirements.

Operating conditions: Consider the maximum operating pressure and temperature of your hydraulic system to ensure that the pump is rated for the required conditions.

Pump type: There are several types of hydraulic pumps, including gear pumps, vane pumps, and piston pumps. Each type has its own advantages and disadvantages, depending on the specific application.

Material and construction: The pump material and construction should be selected based on the compatibility with the fluid being handled and the operating conditions of your application. Common materials include stainless steel, carbon steel, and ductile iron.

Manufacturer reputation and support: Choose a reputable hydraulic pump manufacturer that provides high-quality products and reliable technical support.

Overall, a 40 gpm 3000 psi hydraulic pump is a powerful and efficient solution for heavy-duty hydraulic systems that require high 40 gpm 3000 psi hydraulic pump flow rates and high pressures. By selecting the right pump for your application and performing regular maintenance, you can ensure the optimal performance and longevity of your hydraulic system.

What are some common maintenance tasks for hydraulic pumps?

Regular maintenance is important for ensuring the optimal performance and longevity of hydraulic pumps.

Here are some common maintenance tasks for hydraulic pumps:

Check fluid levels: Check the fluid level in the hydraulic pump regularly, and top up or replace the fluid as necessary.

Inspect hoses and connections: Inspect the hoses and connections for leaks, cracks, or damage. Replace any damaged hoses or connections.

Replace filters: Replace the hydraulic pump filters regularly to prevent contamination of the fluid and to ensure optimal pump performance.

Check for unusual noises or vibrations: Listen for any unusual noises or vibrations coming from the hydraulic pump, as these can be signs of wear or damage.

Inspect the pump shaft seal: Inspect the pump shaft seal for leaks or damage, and replace the seal as necessary.

Check the pump mounting: Ensure that the hydraulic pump is securely mounted to prevent excessive vibration or movement.

Lubricate moving parts: Lubricate any moving parts as recommended by the manufacturer to reduce wear and prolong the life of the pump.

Monitor performance: Regularly monitor the performance of the hydraulic pump, including pressure, flow rate, and temperature, and address any issues promptly to prevent further damage or system failure.

By performing these regular maintenance tasks, you can ensure the optimal performance and longevity of your hydraulic pump and hydraulic system. It’s also important to follow the manufacturer’s recommendations and guidelines for your specific pump and system.