When comparing 10d coil nails to screws in terms of cost-effectiveness, several factors need to be considered:

- Material cost: In general, 10d coil nails tend to be less expensive than screws of similar size and material. Coil nails are mass-produced and manufactured using automated processes, which can result in lower production costs compared to screws.

- Quantity required: The quantity of fasteners needed for a particular project can impact cost-effectiveness. In some cases, nails may be less expensive per unit compared to screws, but a larger quantity may be required to achieve the same level of structural integrity or holding power.

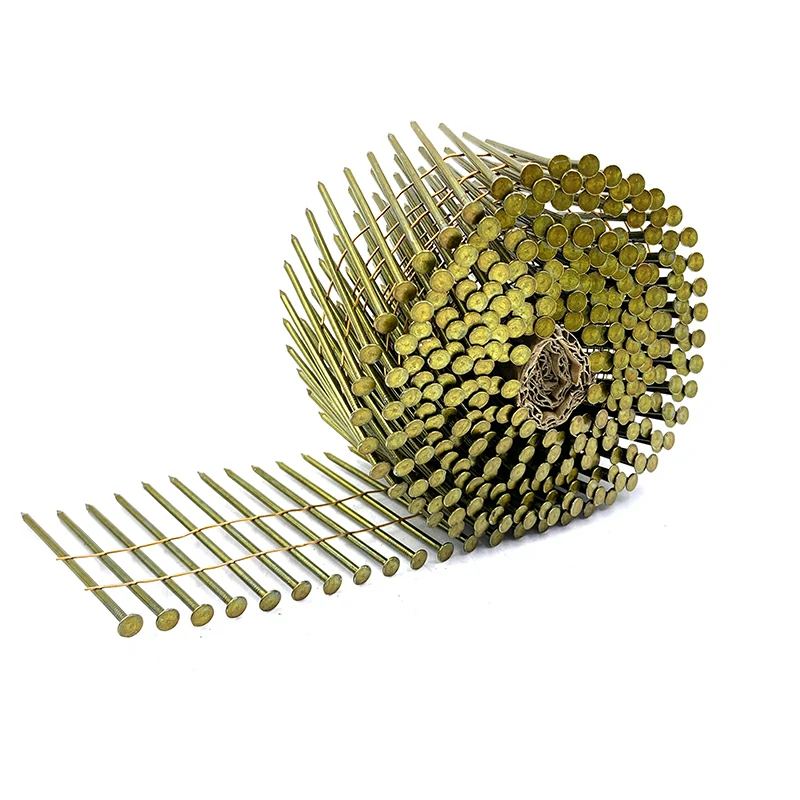

- Fastening method: Coil nails are typically installed using pneumatic nail guns, which offer rapid and efficient installation compared to screws, which require manual driving or use of power screwdrivers. The labor cost associated with fastening can vary depending on the method used, with pneumatic nail guns often being faster and more cost-effective for large-scale projects.

- Application: The specific application and requirements of the project can also influence cost-effectiveness. 10d coil nails In some cases, screws may be preferred over nails due to their superior holding power, especially in applications where structural integrity is critical. However, for non-structural applications or temporary installations, nails may provide sufficient strength at a lower cost.

- Longevity and durability: Screws generally provide better resistance to pull-out and shear forces compared to nails, which may contribute to longer-lasting installations in certain applications. However, for projects where durability is not a primary concern or where regular maintenance and replacement are anticipated, nails may offer adequate performance at a lower initial cost.

- Availability and accessibility: The availability of materials and tools can also impact cost-effectiveness. In some regions or markets, nails may be more readily available and less expensive than screws, making them a more cost-effective option for construction projects.

In summary, the cost-effectiveness of 10d coil nails compared to screws depends on various factors, including material cost, quantity required, fastening method, application requirements, longevity and durability, and availability. While nails may offer lower initial costs and faster installation times, screws may provide superior holding power and longevity in certain applications. It’s essential to consider these factors and evaluate the specific needs of the project to determine the most cost-effective fastening solution.